Hard shot peening

Collisions of the shots which are small and hard balls of steel quickly through the Normal shot peening on the surface after carbonization and induction hardening will enhance the hardness of the parts and fatigue strength.

| Treatment condition |

|---|

Collide the balls of steel on the |

| Metallographic structure |

|---|

|

Retained austenite |

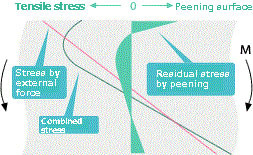

Production mechanism of compressive residual stress

- 1.Retained austenite

- 2.The strain induced transformation by shot projection

- 3.Volume expansion

- 4.Compressive residual stress

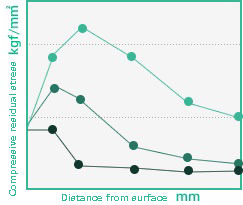

Distribution of compressive remaining stress

after shot peening (carbonization parts)

Hard shot peening

Hard shot peening Usual shot peening

Usual shot peening Without peening / No peening

Without peening / No peening

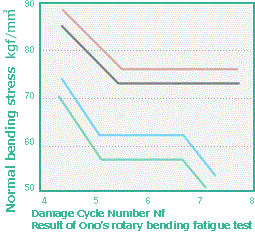

Effect of compressive residual stress

TSCM620Carburizing + Hard shot peening

TSCM620Carburizing + Hard shot peening SCr420Carbonitriding + Hard shot peening

SCr420Carbonitriding + Hard shot peening SCr420Carburizing + Usual shot peening

SCr420Carburizing + Usual shot peening SCr420Carburizing

SCr420Carburizing

Because the tensile stress on the surface can be reduced by high compressive remaining stress occurring from hard shot peening, the effect can see in improving fatigue life.

Equipment

Hard shot peening machine |

The factroy is able to do

Kaita Factory 9-9 Tsukimi-machi, Kaita-cho, Aki-gun, Hiroshima-ken, 736-0034, Japan Tel. +81-(0)82-822-2957 Fax. +81-(0)82-822-7294 |

Hofu Factory 26-1 Shintukiji-cho, Hofu-shi, Yamaguchi-ken, 747-0824, Japan Tel. +81-(0)835-25-3737 Fax. +81-(0)835-25-8626 |