Induction hardening

It is one of the heat treatment methods to harden the surface of an object but not the whole object. This method uses high frequency induction hardening. It is efficient since the necessary portion is hardened, and it is good to minimize thermal deformation rather than quenching throughout. This method is applied widely to machinery parts and automobile parts.

| Principle |

|---|

We apply HF current to heating coil which put around a part as shown in the figure, |

| Metallographic structure |

|---|

Microstructure |

Single shot induction hardening

We generally apply scanning HF induction hardening for a long workpiece. If the workpiece has portion of different diameters, heating and/or cooling will be excessive or insufficient.

Then we apply single shot HF induction hardening for the workpiece by optimizing the shape of the heating coil to the shape of the workpiece, it is possible to heat and cool the workpiece uniformly. It is also possible to minimize the deformation and to get the high strength because of disappearing the stripe pattern, so-called "barber's pole pattern." And we increase the production capacity by separating a heating unit and a cooling unit.

Video presentation of treatment

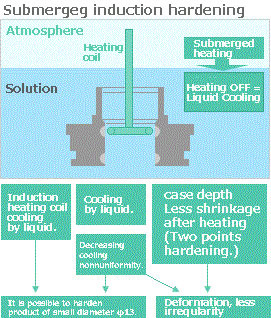

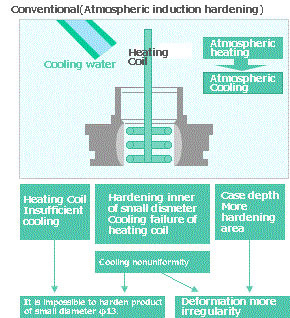

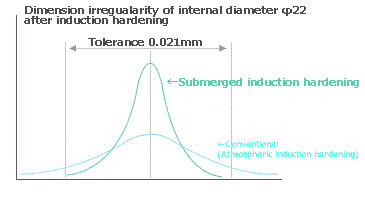

Submerged induction hardening

Apply the induction hardening in a liquid. This makes hardening the narrow internal diameter, thin wall parts and neighbouring areas of the hardened part possible which were said to be impossible because of the limitation on machines and difficulty of heating/cooling before. Plus, it can inhibit forming when hardening. We have records of hardening the inside diameter of a spline.

Comparison between submerged induction hardening and conventional induction hardening

Non-oxidation induction hardening

In general induction hardening, because the scale (oxide film) occurs on the surface, polishing will be done in a later process, non-oxidation induction hardening can connect to reduction of production costs by reducing the scale forming on the surface to make omitting the polishing process possible.

Stationary type induction hardening

It is a heat treatment process that involves not moving a heating coil or workpieces.

Video presentation of treatment

Vertical movement type induction hardening

Vertical induction hardening is applied for the workpieces like round bars, we move a Induction heating coil or workpieces in a longitudinal direction and harden the workpieces.

Horizontal movement type induction hardening

This is applied for products that are going to be hardened on the flat surface mainly and they will be hardened moving the Induction heating coil / product horizontally.

Video presentation of treatment

Full automatic induction hardening

For products that will be treated a large amount like car parts which are all processed automatically including removal of the product to a hardening machine.

Video presentation of treatment

(Turntable type)

(Robotic detachable type)

Related equipment

The factroy is able to do

Nagato Co., Ltd. & Oozu Factory 3-6-24 Oozu, Minami-ku, Hiroshima-shi, 732-0802, Japan Tel. +81-(0)82-282-4361 Fax. +81-(0)82-282-4262 |

Kaita Factory 9-9 Tsukimi-machi, Kaita-cho, Aki-gun, Hiroshima-ken, 736-0034, Japan Tel. +81-(0)82-822-2957 Fax. +81-(0)82-822-7294 |

Numata Factory 2-23-1 ohzuka-nishi, , Asaminami-ku, Hiroshima-shi, 731-3167, Japan Tel. +81-(0)82-848-6021 Fax. +81-(0)82-848-6301 |

Shiwa Factory 190-1 Aza Fukasako, Kanmuri, Shiwa-cho, Higashi-Hiroshima-shi, 739-0265, Japan Tel. +81-(0)82-420-5511 Fax. +81-(0)82-420-5615 |

Tokai Factory 138 Kasuga, Takaoka-Shinmachi, Toyota-shi, Aichi-ken, 473-0921, Japan Tel. +81-(0)565-52-3631 Fax. +81-(0)565-53-4611 |

Hofu Factory 26-1 Shintukiji-cho, Hofu-shi, Yamaguchi-ken, 747-0824, Japan Tel. +81-(0)835-25-3737 Fax. +81-(0)835-25-8626 |

Nagato Heat Treatment (Wuxi) Co., Ltd. NO.5 7th Factory,NO.31 Tuanjie Middle Road, Xishan Economic Development Zone, Wuxi, Jiangsu Province, China Tel. +86-(0)510-8826-7273 Fax. +86-(0)510-8826-7223 |

Nagato Heat Treatment (Thailand) Co., Ltd. 7 /379 Moo 6, Tambol Mabyangporn, Amphur Pluakdaeng, Rayong, Thailand Tel. +66-(0)38-027-473 Fax. +66-(0)38-027-475 |

| Induction hardening | Applicable equipment | Processing factory | ||||||

|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

||

|

Stationary type induction hardening |

○ | ○ | ○ | ○ | ○ | ○ | ||

| Vertical movement type induction hardening |

Vertical movement type induction hardening machine | ○ | ○ | ○ | ○ | ○ | ○ | |

| Horizontal movement type induction hardening | Horizontal movement type induction hardening machine | ○ | ||||||

| Full automatic induction hardening | Full automatic induction hardening machine | ○ | ○ | |||||

| Single shot induction hardening | Single shot induction hardening machine | ○ | ○ | |||||

| Submerged quenching | Submerged induction hardening machine | ○ | ||||||

| Non-oxidation quenching | Oil submerged induction hardening machine | ○ | ||||||