Front Page > Technical Information > Heat treatment for products > Carburizing + Induction hardening

Carburizing + Induction hardening

It’s a technology installed at Mazda corporation and it has a patent.

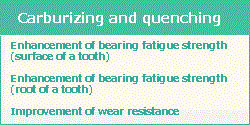

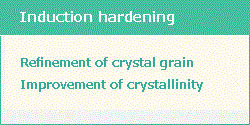

From the induction hardening after carbonization hardening, the crystal grains are refined and grain boundary property during carbonization is improved, as an example, the gear improves in shock strength and conflicting of sporing strength improves at the same time and the strength of the gear gets stronger.

![]()

Comparison between carburizing + induction hardening products and conventional carburizing hardening products

| Crystal grain size | Fracture morphology | |

|---|---|---|

| Carburizing + Induction hardening |  Gc No.11 |

Intercrystalline fracture |

| Conventional carburizing |  Gc No.8 |

Grain boundary fracture |

The factroy is able to do

Kaita Factory 9-9 Tsukimi-machi, Kaita-cho, Aki-gun, Hiroshima-ken, 736-0034, Japan Tel. +81-(0)82-822-2957 Fax. +81-(0)82-822-7294 |

Nagato Co., Ltd. & Oozu Factory 3-6-24 Oozu, Minami-ku, Hiroshima-shi, 732-0802, Japan Tel. +81-(0)82-282-4361 Fax. +81-(0)82-282-4262 |